Spot EIFS Problems Early in Hampton Roads Homes

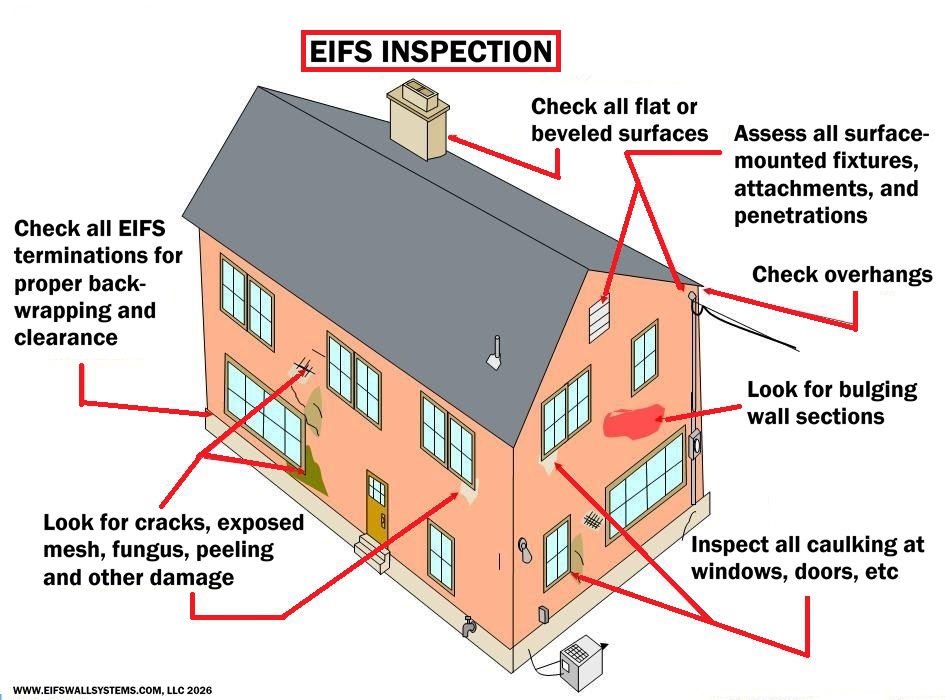

EIFS (Exterior Insulation and Finish Systems) can perform well in Hampton Road’s coastal climate—but only when it’s installed and maintained correctly. Early-stage issues often go unnoticed until moisture intrusion, substrate damage, or mold growth becomes costly and disruptive. Our inspections focus on identifying these problems before they escalate.

Common early EIFS warning signs include cracking at joints, failed sealant transitions, impact damage, improper flashing details, and moisture trapped behind the system. In Norfolk’s humid, wind-driven rain environment, even small installation defects can allow water to migrate behind the finish and compromise framing, sheathing, and insulation.

We specialize in recognizing subtle EIFS deficiencies that builders, homeowners, and property managers often miss. By spotting problems early, you can reduce repair costs, protect structural integrity, and extend the service life of your exterior cladding—while maintaining your home’s appearance and value.

Cracks, Bulges, and Stains Explained

Cracks, bulges, and surface staining in EIFS are often early indicators of underlying installation defects or moisture-related issues. While these conditions may appear cosmetic at first, they can signal more serious problems developing behind the scenes.

Cracks commonly occur at stress points such as window and door openings, control joints, or areas lacking proper reinforcement. They can result from building movement, improper mesh placement, insufficient base coat thickness, or failed sealant joints that allow water intrusion.

Bulges or soft areas typically indicate trapped moisture, adhesive failure, or substrate deterioration behind the EIFS. These conditions suggest the system is no longer properly bonded and may continue to delaminate if not addressed.

Stains and discoloration often point to prolonged moisture exposure, poor drainage, or biological growth. In coastal and high-humidity environments, staining can develop quickly when water cannot exit the wall assembly.

Understanding these warning signs allows property owners to act early—before minor defects turn into structural damage, mold growth, or extensive repairs.

Top Ten Signs of EIFS Problems

1. Moisture Intrusion:

- Stains or Discoloration: Look for water stains, especially around windows, doors, or joints.

- Damp or Soft Spots: Test for areas that feel soft or damp to the touch.

- Mold Growth: Check for visible signs of mold or mildew on the surface or inside walls.

2. Cracking or Damage:

- Cracks in the Finish: Inspect for hairline cracks or larger, visible cracks in the EIFS surface.

- Impact Damage: Look for punctures or dents caused by physical impact (e.g., hail, tools, or debris).

3. Sealant Issues:

- Deteriorated Sealant: Inspect the caulking/sealant around windows, doors, and expansion joints for gaps, shrinkage, or brittleness.

- Separation or Gaps: Check for gaps between the EIFS and adjacent materials.

4. Flashing and Drainage Problems:

- Improper Flashing: Verify that flashing is properly installed around rooflines, chimneys, and windows.

- Drainage Issues: Check for standing water or improper slope that might trap water against the EIFS.

5. Substrate and Attachment Issues:

- Delamination: Tap the EIFS surface to listen for hollow sounds, indicating the system may be detaching from the substrate.

- Improper Installation: Look for missing or inadequate mechanical fasteners.

- Warping or Bowing: Inspect for uneven areas that may indicate structural issues underneath.

6. Insufficient Termination:

- Ground Clearance: Ensure the EIFS terminates at least 6-8 inches above grade to prevent moisture wicking.

- Roof Clearance: Inspect the termination at rooflines to ensure proper spacing and drainage.

7. Interior Signs of Failure:

- Wall Stains: Look for staining or bubbling on interior walls that might indicate water intrusion.

- Peeling Paint or Wallpaper: Check for peeling or bubbling finishes inside the building near EIFS-covered walls.

8. Inspection Tools:

- Moisture Meter: Use a moisture meter to check for elevated moisture levels within the EIFS or substrate.

- Infrared Camera: Perform a thermal imaging scan to identify hidden moisture or temperature anomalies.

- Probe Test: Engage a professional to conduct a probe test if significant issues are suspected.

9. Common Areas for EIFS Issues in Hampton Roads / Norfolk VA:

- High Humidity Effects: The humid climate in Hampton Roads can exacerbate moisture retention.

- Storm Damage: Frequent storms and hurricanes can cause impact damage or exacerbate drainage issues.

- Proximity to Water: Properties near the coastline or waterways are more prone to moisture-related problems.

10. Professional Inspection Recommendation:

If you identify any of the signs above, consult a professional EIFS inspector or construction specialist in the Norfolk area. They can perform more advanced diagnostics and recommend appropriate repairs or remediation.

Why Hampton Roads Weather Accelerates Issues With EIFS – Rain, salt air, and wind effects.

Hampton Roads’ coastal climate accelerates building envelope issues like those in EIFS systems due to frequent rain, corrosive salt air, and high winds. These elements cause faster material degradation, moisture intrusion, and structural wear compared to inland areas. Local construction professionals often prioritize resilient materials and regular inspections to mitigate these effects.

Rain Effects

Heavy rainfall and tidal flooding from nor’easters and hurricanes drive water behind EIFS layers, promoting delamination and mold growth. Prolonged humidity traps moisture in walls, weakening insulation and finishes over time. Annual inspections after storms help detect early water damage.

Salt Air Corrosion

Salt-laden air from the Chesapeake Bay and Atlantic accelerates corrosion of metal fasteners and degradation of sealants in EIFS assemblies. This leads to cracking and loss of adhesion in finish coats, especially on coastal exposures. Using corrosion-resistant components extends system life.

Wind Impacts

Strong coastal winds, often gusting over 40 mph, lift EIFS finish and base coats while driving rain into micro-cracks. This exacerbates impact damage from debris during storms, compromising air barriers. Wind-rated designs and reinforced mesh improve durability.