VIRGINIA BEACH EIFS INSPECTIONS

- Moisture Intrusion

- Sealants & Flashing Integrity

- Proper Installation & Clearances

EIFS & stucco inspectionS & repair in Hampton Roads since 1991

Stop leaks before they destroy your walls.

Inspections are scheduled within 48 hours in Norfolk, Virginia Beach, Chesapeake, and surrounding areas.

EIFS Maintenance Program

Maintaining EIFS

An EIFS Maintenance Program (for Exterior Insulation and Finish Systems, also known as synthetic stucco or systems like Dryvit, Sto, Parex, or Senergy) is a structured, proactive plan to preserve the system’s performance, appearance, energy efficiency, and longevity. Well-maintained EIFS can last 30–60+ years, but neglect often leads to moisture intrusion, cracks, mold, or costly repairs.

Major manufacturers (e.g., Dryvit’s DryvitCARE™, Sto’s reStore, Senergy’s Renew) and industry groups like EIMA (EIFS Industry Members Association) and AWCI (Association of the Wall and Ceiling Industry) emphasize regular inspections, cleaning, and timely repairs. Modern EIFS (especially “EIFS with drainage”) is low-maintenance, not zero-maintenance—focus on preventing water intrusion, as that’s the primary risk.

EIFS & Stucco Repair

Over time, exterior insulation and finish systems (EIFS) can crack and chip due to weathering and age. When you notice signs of wear and tear, it is vital to schedule EIFS repair services to restore the structure’s original integrity. Our EIFS repair process begins with a thorough inspection of the structure and the health of the EIFS. Once the structure’s health is reviewed, our team performs the necessary EIFS repairs to restore its original integrity and appearance.

Key Components of an Effective EIFS Maintenance Program

Routine Visual Inspections

Perform these regularly to catch issues early. Frequency recommendations vary by exposure (e.g., coastal/humid areas need more), but best practices include:

- Homeowners/property managers — Every 3–6 months (quick visual checks).

- Professional inspections — Annually or every 2–3 years (or after severe weather).

- After major events like storms, hail, or high winds.

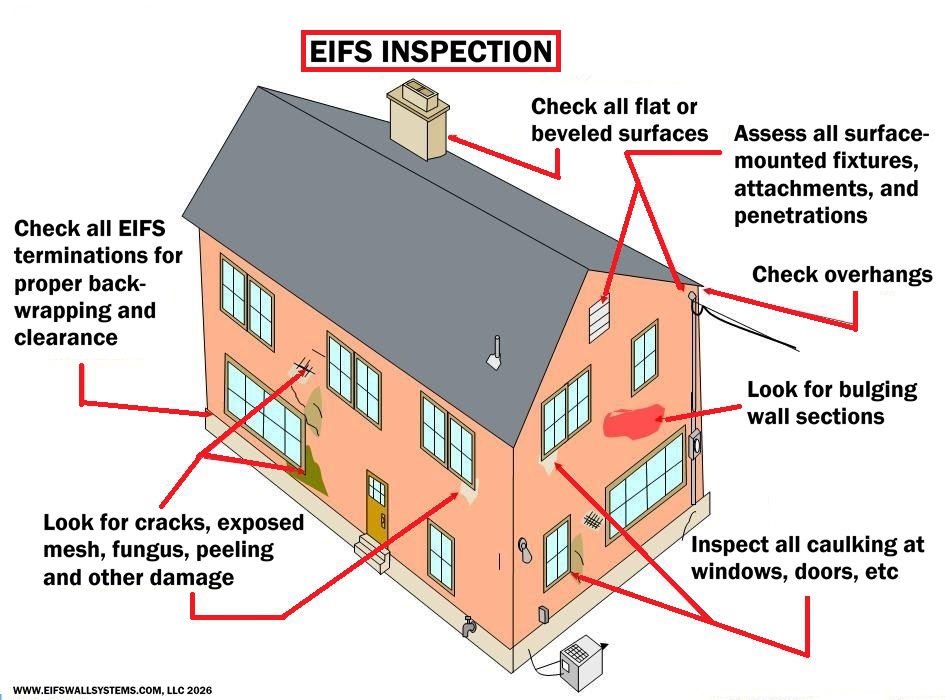

What to Check (Basic Checklist):

Dirt, algae, mildew, or staining accumulation.

Cracks, chips, blisters, bulging, or delamination in the finish/base coat.

Gaps, shrinkage, or failure in sealants/caulking around windows, doors, penetrations (pipes, vents, lights), expansion joints, and terminations.

Proper clearance: EIFS should terminate ≥6 inches above grade/soil; check for bridging or contact with landscaping/grade.

Signs of moisture: Stains, efflorescence, mold/mildew, bubbling, or soft spots.

Drainage paths: Ensure weep holes, kick-out flashing, and base accessories allow incidental water to escape (critical in drainage-type EIFS).

Impact damage: Dents, punctures, or abrasions from vehicles, landscaping, etc.

Cleaning

Frequency: Every 1–3 years, or as needed (more often in polluted/humid areas). Use gentle methods: Low-pressure rinse (under 200–300 psi), soft brush/cloth, and manufacturer-approved mild detergent or cleaners. Avoid: High-pressure washing, abrasive tools, harsh chemicals, or power washing that can damage the finish or drive water behind the system. Many acrylic finishes are dirt-resistant; some have hydrophobic additives to shed water/dirt.

Repairs & Sealant Maintenance

Address minor issues immediately (e.g., patch cracks/holes with compatible EIFS patching compounds; reseal joints with silicone-based sealants compatible with the system). Larger damage (e.g., water intrusion, mesh exposure, or substrate issues) requires professional repair—do not DIY beyond minor surface fixes. Reapply sealants every 5–10 years, or sooner if they fail. For resurfacing/refreshing: Options such as recoating or manufacturer restoration programs (e.g., DryvitCARE Platinum Warranty) can enhance aesthetics and extend service life.

Sample Annual Maintenance Schedule

- Q1/Q2/Q3: Quick visual self-check (10–20 minutes walking perimeter).

- Annually: Professional inspection + gentle cleaning if dirty.

- Every 2–5 Years: Deep clean, sealant refresh, minor repairs.

- As Needed: Immediate fixes for damage; full restoration if widespread issues appear.

- Repainting: Every 10-15 years.

Benefits of a Formal Program

- Prevents expensive water damage/mold/rot.

- Maintains energy efficiency (continuous insulation).

- Preserves warranty (many require documented maintenance).

- Enhances property value and curb appeal.

Documentation & Professional Involvement

Keep records: Photos, dates, reports, repairs, and cleaning logs.

Hire certified pros: Look for AWCI-certified EIFS inspectors/mechanics (via AWCI’s National Certification Registry) or manufacturer-trained applicators.

Follow manufacturer-specific guidelines (e.g., Dryvit, Sto, Senergy technical bulletins) as systems vary slightly.

$250 EIFS Inspection For Hampton Roads Homeowners!

Offer Ends January 31, 2026

We’re committed to delivering a hassle-free experience and making sure you’re delighted every step of the way.