Why Every Detail Matters:

The Many Facets of Inspecting EIFS

In some projects, the specifications call for EIFS inspection as part of a private contractual requirement tied to the scope of work. In other cases, inspection is mandated by statute, such as when building codes require it. That said, most EIFS installations are not formally inspected. EIFS has generally not been classified as a critical construction element—such as structural welds or elevators—that routinely require inspection.

When EIFS inspection is required, it adds both time and cost to the project, often prompting discussion around how much inspection is necessary and why. These conversations typically focus on ensuring a properly constructed, long-lasting wall system while managing budget and schedule impacts.

Will EIFS inspection become more common? That remains to be seen. However, efforts are currently underway to establish a national consensus protocol for EIFS inspections. This article provides an early look at what may be ahead and helps prepare stakeholders for potential future inspection requirements.

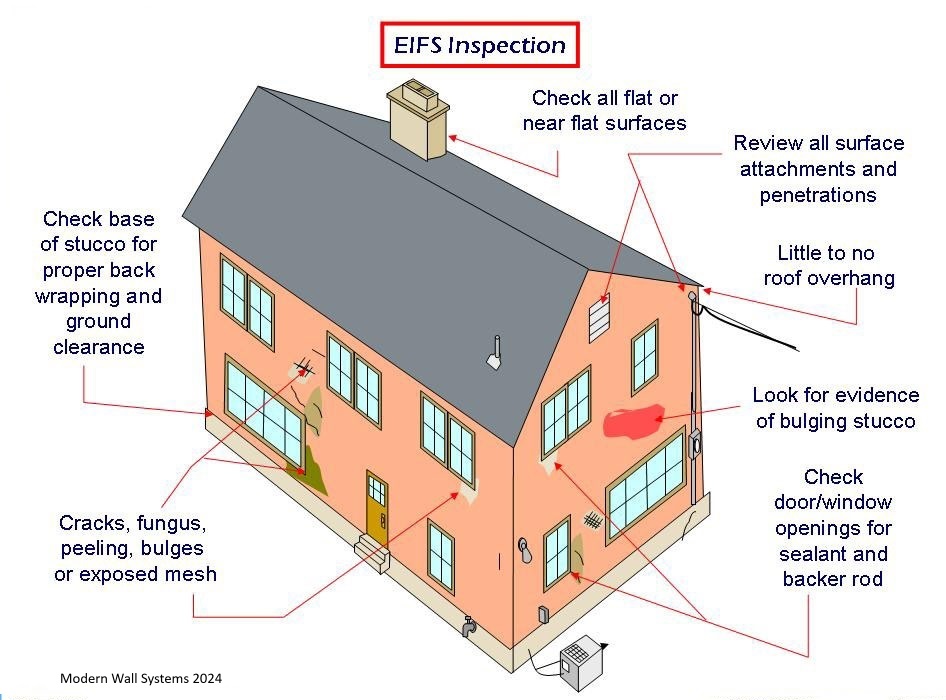

Visual Inspection, Testing, or Sampling?

When developing inspection standards, the goal should be efficiency and cost-effectiveness. That means keeping inspections focused on what truly impacts the performance and appearance of the finished EIFS. Overanalyzing details that have no real effect adds unnecessary time and cost.

Whenever possible, inspections should rely on visual, non-destructive methods. Sampling and laboratory testing are more invasive, time-consuming, and expensive, and should be used only when truly warranted. With regular inspection visits, most critical issues can be identified early and corrected without delaying the project.

An effective inspection program should therefore be straightforward and practical. If an owner wishes to include additional layers of verification—such as checking wall flatness or other enhanced criteria—those requirements can be added as optional services and priced accordingly. After all, does it make sense to require moisture readings of substrates on a project in Reno when there hasn’t been rain for two weeks?

Beyond the Basics: Additional Inspection Considerations

The range of potential inspection items is virtually unlimited. These optional inspection elements are project-specific and should be tailored to address the unique priorities and risks of each project.

For example, on a high-end retail façade with large, uninterrupted wall areas—especially where downlighting is used to illuminate the building at night—tighter flatness tolerances for the finish coat may be appropriate. In such cases, the final wall inspection may reasonably include observations of the completed façade under nighttime lighting conditions to verify overall appearance and performance.

THE INSPECTOR’S ROLE

It may seem foolish to say but the inspector’s role is to inspect. This means, at its most basic, to report on what is going on and has happened. Literally, this can be making a record of how things have been done, but may also extend to getting involved with mediating solutions to defects, of running tests, taking samples or even designing solutions. Normally, inspectors do not take on these additional roles-it’s not normally part of their contract. For instance, re-engineering construction details is the architect’s job, not the inspector’s.

How Often Is Inspection Required?

1. Construction Phase Inspection (Building Department)

During initial construction—if EIFS is part of the permitted work—the local building department will perform required inspections at applicable stages of the project as part of the Virginia Uniform Statewide Building Code (VUSBC) inspections before final approval and issuance of a certificate of occupancy. Permit requirements trigger these inspections and go with the progress of construction work, not on a recurring schedule once the building is completed.

2. Special or Contractual Inspections

Separate from permit inspections, special inspections for EIFS may be required on a project-by-project basis if specified in the construction documents or specifications, or by the building official. For example, the International Building Code and versions adopted into Virginia’s code require special inspections of EIFS in certain conditions—unless exceptions apply (e.g., EIFS over drainage-capable water-resistive barriers or over masonry/concrete). These are typically one-time or staged during construction rather than ongoing routine inspections.

3. Post-Construction / Maintenance Inspections

For finished buildings, there is no universal legal mandate in Virginia that homeowners or property owners must have EIFS inspected annually or on any set schedule under state code. Routine inspection frequency is usually a best practice recommendation, not a statutory requirement.

Conclusion

Inspection can provide significant value when applied thoughtfully. In most cases, there is no need for excessive oversight—EIFS has been successfully used for decades, and experienced contractors understand how these systems are properly installed. Inspection becomes most beneficial on projects with complex detailing, unconventional assemblies, or specialty EIFS systems that differ from standard barrier applications.

In practice, EIFS-related issues typically stem from fundamental installation or detailing errors, especially where the system interfaces with adjacent wall components. Identifying these issues early helps prevent systemic failures, avoids rework, and can result in substantial long-term cost savings.

Looking ahead, inspection is likely to play a more prominent role as national, consensus-based standards continue to evolve and find their way into project specifications. These developments will bring greater clarity, consistency, and predictability to EIFS inspection practices across the industry.